Using satellite AIS Data to track maritime supply chain

How Gravity Supply Chain uses AIS to provide end-to-end supply chain visibility for greater management control.

Maritime Case Study Gravity Supply Chain Case Study

Tracking supply chain on the high-seas with satellite AIS data API

Executive Summary

Gravity Supply Chain Solutions is the developer of real-time, supply chain management solutions. Gravity Supply Chain supports companies in their journey to digitize their supply chains, by seamlessly connecting their global end-to-end operations, supplier base, logistics networks, and customers on a single platform that provides intelligent data management, automation, and visibility.

Gravity partnered with Spire to enhance the level of visibility it could provide to its customers. With Spire, Gravity is able to offer data on the visibility of vessels while they are in transit, enabling users to better manage their supply chains with data-driven decisions.

Challenges

The objective of Gravity is to provide our clients with end-to-end visibilityof their supply chains, from product concept, sourcing, and ordering all the way to receipt at the destination warehouse. The biggest challenge we faced was ensuring there were no blind spots or gaps in the visibility we provided.

To obtain visibility, we made the decision not to rely on the data provided by third party logistics (3PLs) for vessel positions. While 3PL data is easy to obtain, it is often out of date and prone to error since it is mostly keyed in manually by a human operative. Furthermore, 3PL data typically only tells you when a vessel has departed or arrived at a destination, and rarely provides visibility while a vessel is in transit.

The Value of Fresh and Accurate Position Data

We wanted Gravity to be an agnostic platform that did not depend on 3PL data. Instead, we wanted accurate data from a reliable source that was frequently updated and provided visibility of goods in transit, thus ensuring no gaps or inaccuracies in the visibility we offered to our customers. AIS data, specifically satellite AIS data picks up signals from ships across the world’s marine channels with an average latency of 45 minutes enabling our customers to track their cargo across the high-seas, not just port arrivals and departures.

Results, Return on Investment and Future Plans

Our collaboration with Spire has hugely benefitted Gravity. Being able to provide accurate end-to-end visibility is a powerful selling point for us and the ease-of-use of their API allowed us to get up and running in no time. We are already in discussion with Spire regarding their ads-b data (aviation) crucial for air cargo tracking, and their maritime weather API; weather forecasts are essential when it comes to predicting ETAs and route efficiency. We view Spire as a long term partner and look forward to continuing to work together in order to provide our customers with the most accurate and reliable shipment data available.

Learn More

How Spire Helped

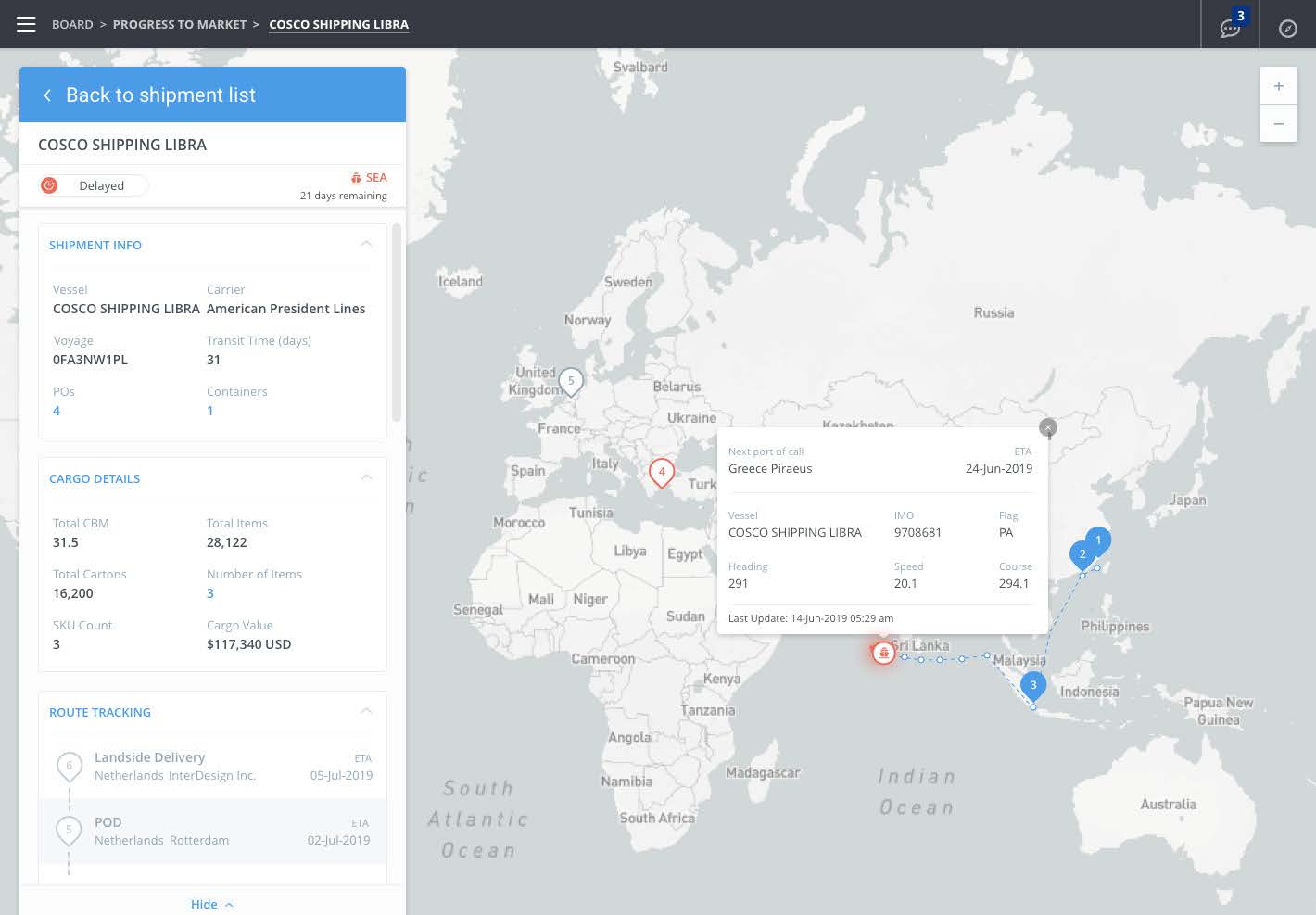

Spire Maritime provides us with an external, valid source of decoded satellite AIS data through a simple API. Their messages API integrates seamlessly with our proprietary solution and allows data to be filtered by a number of important fields such as the IMO number, the last port of call, where the vessel is headed, the speed at which it’s travelling, and the next destination. We use that data to provide our users with true end-to-end supply chain visibility, enabling them to track where their cargo is at any time, including when it is in transit.

This data empowers our users to accurately predict ETA times and make proactive, data-driven decisions to efficiently manage their supply chains to ensure complete and on-time deliveries. We also reduce our users’ administrative work, because they don’t have to spend time calling or emailing their 3PL asking about where their vessel is or when it will arrive.

Proven Customer Value

In one use case, a Gravity customer was able to capture 100 percent of ETA changes to inbound vessels, versus 43 percent using a previous system that relied heavily on manual updates. In another case, a Gravity user significantly reduced their administrative work, resulting in a six percent reduction in labour costs.