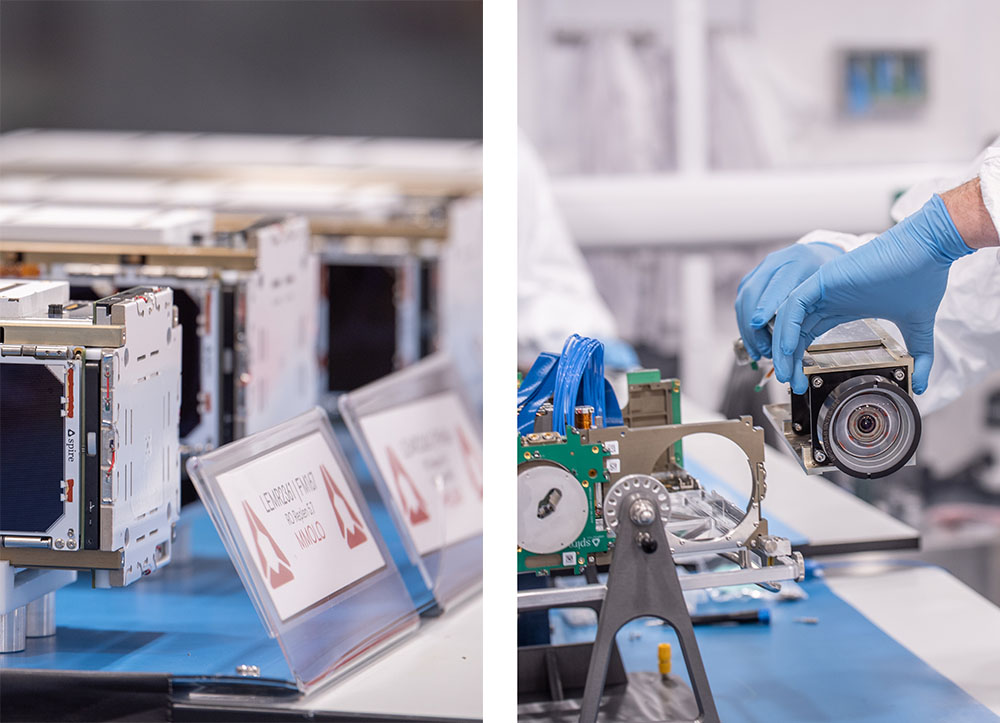

Precision satellite manufacturing, made easy

Get to space quickly and reliably. Be in control of your schedule. Utilize vertically integrated, state-of-the-art manufacturing facilities and end-to-end capabilities. Spire makes this a reality, putting you in control, meeting your objectives and delivering on missions successfully.

Total control

With full control over the supply chain and our purpose built testing equipment, designed to simulate space conditions, Spire provides the highest standard of manufacturing combined with accelerated testing, guaranteeing precision and efficiency throughout your journey.

In-house expertise

Spire’s state-of-the-art, 3000m², satellite manufacturing facility in Glasgow UK, streamlines the entire manufacturing and testing process under one roof. Home to Class 10,000 cleanrooms and cuttingedge equipment, every step is meticulously planned and conducted in-house by our industry leading engineers.

Constellation capacity

Spire’s facilities and manufacturing process are ISO9001:2015-certified, designed for serial manufacturing with the capability to fast-track satellite constellation delivery, enabling the annual capacity for the design, manufacture and testing of 200+ satellites.

Our manufacturing heritage

Our satellites are built on the internally developed LEMUR (Low Earth Multi Utility Receivers) bus, a platform with an impressive 600+ years of combined flight heritage and a track record of over 30 design iterations, showcasing continuous development and innovation. The LEMUR design is adept at meeting the diverse requirements of various dispensers, ensuring successful deployment.

Spire is ready to utilize our cutting-edge Manufacturing, Assembly, Integration and Test (MAIT) facilities in the delivery of your mission.

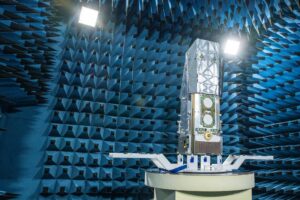

In-house environmental testing equipment

Spire has everything you need under one roof, to perform flight acceptance testing on your satellites and integrate them into flight dispensers, accelerating the production cycle whilst maintaining schedule and quality control.

Cleanrooms

Class 10,000 clean rooms and cutting-edge equipment

Radio Frequency (RF) anechoic chambers

Fine-tunes and assesses the RF systems of your satellites for seamless operation.

Vibration tables

Replicates the vibrations of launch and space travel to test satellite structure.

Sun Simulator

Evaluates your satellites ability to withstand extreme heat and UV exposure in space.

Vacuum exposure machines

Recreates space’s vacuum and assesses your satellite’s performance in the environment.

Thermal vacuum chambers (TVAC)

Simulates the extreme temperatures of space along with the lack of air to ensure your satellites can withstand the harsh conditions.

Thermal chamber

Simulates the extreme temperatures of space to ensure your satellites can withstand the harsh conditions.

De-gaussing system

Eliminates residual magnetic dipoles for precise pointing operations.

Unlocking payload potential

Our facility enables your payloads to be seamlessly integrated into the satellite, giving you peace of mind, utilizing our optimized design processes and engineering. We work to deliver your constellation to your deadline and to our highest standards.

We also offer our support in on-site functional testing (RF & Optical testing), if your constellation so requires. At Spire, we provide our expertise throughout the satellite manufacturing process and beyond, mitigating risk, optimizing efficiency, giving you the confidence to act with certainty.

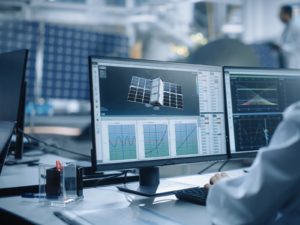

End-to-end expertise

Our expertise supports your idea from concept to space, through our in-house vertically integrated end-to-end processes we work with you every step of the way, understanding, developing and meeting your mission objectives.

Mission design

We help you design the optimum solution for your business, defining the timeline of your project.

Manufacturing

We build your satellite constellation in-house using our state-of-the-art facility, in less time, more reliably and to the highest standards.

Testing

Our in-house testing capability stimulates space conditions to ensure your satellites are fully functional upon deployment.

Integration

We integrate your satellites into flight dispensers, ensure an accelerated production cycle, whilst maintaining full control.

Launch

Our rapid and reliable access to LEO, 385 to 650km, through our qualified launch partners, gives you flexibility and protection for your launch day.

Seamless deployment integration

As part of the space service, Spire will select and procure compatible flight dispensers for your mission. LEMUR satellites are designed to envelope the requirements of a diverse set of dispensers, and have been successfully deployed using the following products:

- ISIS Quadpack

- Nanoracks NRCSD

- ECM/ Exolaunch CSD 12U

- Rocketlab Maxwell

- TyVak RailPOD

- Astrofein PSL-P 12U

With the impressive LEMUR legacy and our deployment expertise, your organization benefits from a proven platform that guarantees reliability and performance beyond comparison.

From manufacturing to launch to deployment

Spire goes beyond the development of your satellite. We support our partners to launch and deployment, leveraging our 600+ years of flight heritage with our track record of 175+ satellites launched across 35+ launch campaigns. Your Spire-made satellite constellation is ready to go, lets get to orbit together.